- 24th Dec, 2024

What Is PVD Coating? Here Is Everything That You Need To Know

You must have come across the term PVD coating, especially when it comes to purchasing furniture or decorative elements. PVD-coated products have gained huge popularity across various industries due to the range of benefits that they offer. They are known for their aesthetics and functional purposes, making them the top choice both among manufacturers and buyers.

But what is PVD coating? In this blog, we will cover everything about PVD coating, including its features, appearance, types and applications.

Understanding PVD Coating

PVD coating is a technique that involves the transfer of a material onto a substrate. There are various methods of PVD coating but the most common one includes vaporising a solid metal and then allowing it to deposit on the desired object, resulting in a thin and durable finish. During the process, the surface of the object that is to be coated is changed and replaced with new mechanical, chemical, electrical and optical characteristics.

PVD-coated stainless steel products are widely used for their enhanced properties, which makes them the suitable choice for various applications.

What Are The Types Of PVD Coating?

PVD coating is done using various methods. Each one has the same working principle; the only difference is how the material is evaporated during the technique. Here are some of the common types.

- Thermal evaporation: It is one of the basic forms of PVD coating. The procedure involved heating the target material in a vacuum environment and then depositing the evaporated material onto a substrate, forming a thin film.

- Sputter Deposition: It is a technique where the main material is bombarded with energetic ions and then the emitted particles are deposited onto another surface.

- Arc Vapour Deposition: Here a high-energy electric arc is used to vaporise the metal particles, which are then condensed onto the substrate.

- Ion plating: In this method, the target material is ionised from various sources, especially noble and reactive gases, which are then deposited to form a thin film.

- Electron beam evaporation: This involves heating the material with an electron beam and then condensing at a very high melting point.

Key Features Of PVD Coatings

PVD-coated stainless steel products have the following features.

- Durability: PVD coating makes the materials extremely hard, hence enabling them to withstand scratches, chipping, and abrasions.

- Resistant to corrosion: Due to the tight bonding of the materials during the coating process, the products are resistant to corrosion and oxidation. This makes them suitable for use in harsh environments.

- Aesthetic appeal: PVD materials are highly customisable. They come in a variety of colours and textures, serving both functional and decorative purposes.

- Improved mobility: PVD materials have reduced friction between the moving parts. This improves the performance of its uses in the medical and industrial sectors.

- Eco-friendly: PVD coating does not involve using harsh or toxic chemicals. Hence they are environmentally friendly and offer a cleaner alternative.

What Is The Appearance Of PVD-Coated Materials?

PVD-coated stainless steel products have a shiny and metallic finish. The coatings usually give a smooth, reflective, and polished appearance, thereby enhancing the aesthetics of the decor and giving a high-end look. The shining and mirror-like finish offers a clean and tidy look, making them the best choice for ornamental jewellery, furniture items and more.

Applications Of PVD Coating Materials

PVD coating is creating waves in various industries such as aerospace, medical, optical, electronics, automotive, architectural hardware, machinery, and other consumer items like furniture and jewellery.

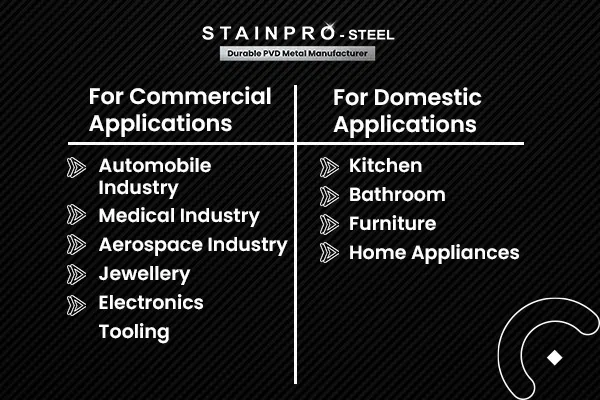

They have a wide range of commercial and domestic uses.

For commercial applications

- Automobile industry: Used for engine parts, wheel trims, and rims.

- Medical industry: Used in surgical instruments and implants.

- Aerospace industry: Used in coating turbine blades and other components.

- Jewellery: Used in a variety of gold and silver items in different colours.

- Electronics: Used in coating connectors, switches and screens.

- Tooling: Used in drills, milling cutters and other cutting tools.

For domestic applications

- Kitchen: PVD coating is used in cookware, sinks, door pulls, cabinet knobs, etc.

- Bathroom: Can be used for showerheads, soap dispensers, and taps.

- Furniture: Can be used for items in residential, office, and commercial purposes.

- Home appliances: Used in appliances like refrigerators and dishwashers.

Conclusion

PVD coating offers several advantages, making the products the top choice. They are long-lasting, low maintenance, cost-effective, and can retain their look for a lifetime. So, if you are looking for PVD-coated stainless steel products, get in touch with StainPro Steel. They are a leading name in the PVD coating industry with an experience of over 30 years. They use high-quality steel and innovative designs to ensure that you get the best product for home, office and commercial spaces. Their products are known for unmatched precision and expert craftsmanship. From furniture to architectural accents, we manufacture every item that will suit your style and requirements.